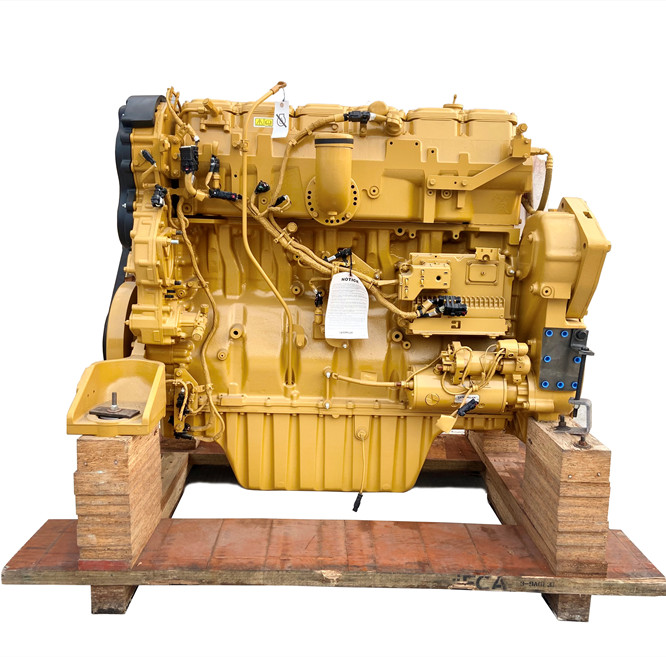

Cat® C15 Industrial Diesel Engine -New CAT Engins

The Cat C15 Industrial Diesel Engine is renowned for it […]

The Cat C15 Industrial Diesel Engine is renowned for its exceptional performance, reliability, and efficiency, making it a preferred choice for a wide range of industrial applications.

Here’s an overview of its key performance strengths and maintenance considerations:Performance Strengths

1. Power and Torque: The Cat C15 delivers an impressive power range of 440 to 595 horsepower, with maximum torque reaching up to 2,507 Nm at 1,200 RPM. This robust performance ensures it can handle heavy-duty tasks with ease, making it ideal for demanding applications such as construction, mining, agriculture, and material handling.

2. Efficiency and Emissions: The engine features advanced technologies like the ADEM A4 Electronic Control Unit (ECU) and a clean emissions module incorporating DOC, DPF, and SCR technologies. These innovations not only optimize fuel consumption but also ensure compliance with stringent emission standards, such as China Stage II, U.S. EPA Tier

3 equivalent, and EU Stage IIIA equivalent.3. Durability and Reliability: Built with high-quality materials and world-class manufacturing processes, the Cat C15 is designed to withstand harsh operating conditions. Its robust construction ensures long-lasting performance and minimal downtime.

4. Flexibility and Customization: The C15 offers a wide range of factory-configurable ratings and options, allowing it to be tailored to specific application needs. This flexibility, combined with its compact size and multiple installation options, makes it suitable for a variety of equipment, including compressors, excavators, and generators.

5. Regeneration Technology: The transparent regeneration technology allows operators to continue working without interruption, enhancing productivity. Additionally, the 5,000-hour Diesel Particulate Filter (DPF) service interval reduces maintenance frequency and keeps the engine running efficiently.

Maintenance Considerations

1. Regular Oil Changes: Adhering to the recommended oil change intervals is crucial for maintaining engine performance and longevity. The Cat C15 typically requires an oil change every 500 hours, depending on the application and operating conditions. Using high-quality SAE 15W-40 or 10W-30 engine oil is recommended.

2. Cooling System Maintenance: Regularly inspect and maintain the cooling system to prevent overheating. This includes checking coolant levels, inspecting hoses for wear, and ensuring the radiator is free from debris.

3. Fuel System Care: The engine’s fuel system should be kept clean and free from contaminants. Regularly inspect fuel filters and ensure the use of high-quality fuel to prevent issues such as poor fuel atomization and reduced power output.

4. Air Intake System: Ensure the air intake system is free from dust and debris. Regularly inspect and clean or replace air filters to maintain optimal airflow and combustion efficiency.

5. DPF Maintenance: The Diesel Particulate Filter (DPF) should be serviced every 5,000 hours to remove ash and maintain its effectiveness. Proper DPF maintenance helps reduce emissions and ensures the engine runs smoothly.

6. Scheduled Inspections: Regularly scheduled inspections and maintenance checks can help identify potential issues early, preventing costly repairs and downtime. Utilize the Cat S•O•S (Sample Oil Service) program to monitor oil and coolant conditions and determine appropriate maintenance intervals.

7. Dealer Support: Leveraging the global Cat dealer network provides access to expert service technicians, genuine parts, and comprehensive support. This ensures that any maintenance or repair work is performed to the highest standards, backed by Caterpillar’s warranty and extended service coverage options.In summary, the Cat C15 Industrial Diesel Engine combines powerful performance, efficiency, and durability with straightforward maintenance requirements. By adhering to recommended maintenance practices and leveraging the extensive support of the Cat dealer network, operators can maximize the engine’s lifespan and ensure consistent, reliable performance in even the most demanding applications.